Mirage Machines

Since joining the Enerpac portfolio, the design innovation of Mirage machines has continued to deliver new products that help get the job done faster, safer, and smarter. Explore the full Mirage product line from flange facing machines, milling machines, hot tapping, drilling and tapping machines to clamshell pipe cutters, decommissioning and band saws. All backed by Enerpac training, application support and service.Design & InnovationMirage Portable Machine Tools are the result of over 25 years of expertise and innovation. The pioneering spirit continues under Enerpac ownership through our commitment to new product development. Watch out for more new tools being launched in the near future!

Continuous Improvement

Our specialist manufacturing operation is ISO9001 certified. This means we drive a culture of continuous improvement. Our team members are encouraged to find ways to improve today, tomorrow, and long into the future.

Specialist Support, Experience & Expertise

Each machining project presents difficult and unique challenges. Making the right choice for your next and any future projects can be complex. That is why our team is eager to support you through every step on your journey. Whether it is choosing the right specification, commissioning your machine, or maintenance – we’re with you all the way.

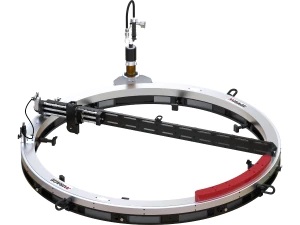

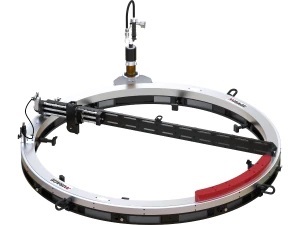

Mirage Flange Facers are known for precision construction, the results they deliver, and how easy they are to set-up on-site. These high-performing machines produce continuous groove facing feeds to ASME standards for the oil & gas, power generation, and petrochemical industries.

MM-I Series feature

• Hardened slideways for long term accuracy

• High torque low noise drive

• Heat exchanger machining accessories available on most models

Applications

• Heat exchanger flanges

• Hub profiles

• Lens ring joints & raised face flanges

• Recessed gaskets and spigots

• Ring type joint grooves (RTJ)

• SPO compact flanges

• Swivel ring & TECHLOK flanges

• Welding preparations

Surface finish & accuracy

All Mirage Flange facing Machines provide a serrated finish with 30-55 grooves per inch and a resultant roughness of between Ra 3,2-12,5μ (125-492 micro inches). Geared multiple continuous groove facing feeds for a gramophone finish (ASME Standard).

Clamshell Cutters

Clamshell cutters in the Enerpac range remain true to the pioneering designs that made DL Ricci the ‘go-to’ brand for

machinists worldwide. Outstanding performance and a comprehensive choice has seen them used widely for applications in new construction, decommissioning, component replacement, fabrication, and maintenance.

Robust and efficient pipe cutting and bevelling

Designed for any industry that needs pipe or tube cutting, or any pipe end preparation weld repair. This may be in oil and gas sector, power generation, ship building/dock yards, or processing plants during maintenance and shut downs.

Applications

- Clamshell body

- Locators & extensions covering the full range

- Slides

- Motor & Mounting

- Air Caddy

- Tool Kit

- Manual

- Shipping crate.