Tangye Hydrapak Pumps

What if there is no power supply?

Hi-Press Hydrapak Pumps are the best and most reliable sources when a power supply is unavailable or fails. Hydrapaks Pumps are globally used as a backup system and provide an alternative pumping mechanism when power packs or power sources fail.

Tangye’s Hydrapak pumps have the following features:

•Fast: The two-speed operation enables quick preload or no-load operation.

•Compact: Despite being small, it has a 700 bar pressure capacity.

•Portable: lightweight aluminium keeps weight down to 4.5kg.

•Safe: Optional factory-fitted relief valve prevents over-pressurisation.

•Range: Six models ranging from 110 bar to 700 bar are available.

•High Flow: Interchangeable plungers allow the selection of optimum pressure/flow characteristics

•Fluid Compatibility: The standard pump contains nitrile rubber seals suited for paraffin, glycerin, mineral oils, water, and oil/water emulsions. We do not recommend exposing the pump body to water for an extended period. After using salt water in the pump, flush it thoroughly. Ethylene Propylene (E.P) seals are available to order for applications using phosphate ester-based hydraulic fluids and vegetable-based brake fluid. E.P seals are compatible with Skydrol 500B and LD4. If you are unsure or have any concerns, please contact our technical support team.

•Pressure Relief Valve: A factory-set pressure relief valve may be fitted to the Hydrapak pump and set to any pressure between 56 and 700 bar. We strongly advise that all hydrapaks be provided with a pressure relief valve to prevent overloading and exceeding maximum safe working pressures.

•Gauges: 100mm gauges and a fixing kit are available for horizontal mounting of a pressure gauge above the top face of the pump. A vertical mounting kit is a must needed for pumps with double-acting valves. Six standard Gauges corresponding to the six standard pressure ratings are available

•Double Acting Valve: A three-position four-port valve for managing double-acting cylinders is available as a factory option. The valve outputs are 3/8 NPT tapped. There is no release valve assembly fitted to the pump body. Despite having minimal internal leakage, isolation valves should be used in circuits where pressure must be maintained.

•Interchangeable Plungers: High/low-pressure plunger kits can be supplied to change the pressure/flow characteristics to any of the six standards

Tangye Hydrapak Pumps

| Model No | Description | Bar | PSI |

|---|---|---|---|

| Hydrapak PHO0000 | Hydrapak Pump | 0-1000 | 14,500 |

| Hydrapak PHO1000 | Hydrapak pump | 0-700 | 10,000 |

| Hydrapak PHO2000 | Hydrapak pump | 0-552 | 8000 |

| Hydrapak PHO3000 | Hydrapak pump | 0-448 | 6,500 |

| Hydrapak PHO4000 | Hydrapak pump | 0-310 | 4,500 |

| Hydrapak PHO5000 | Hydrapak pump | 0-172 | 2,500 |

| Hydrapak PHO6000 | Hydrapak pump | 0-110 | 1,600 |

| Hydrapak PHO6000 | Hydrapak pump with relief valve and gauge on a 1 gallon tank | 0-700 | 10,000 |

| Hydrapak PHO11RGEP | Hydrapak pump with relief valve and gauge on a 1 gallon tank (EP seals) | 0-700 | 10,000 |

Tangye Hydrapak Accessories

| Model No | Description | Bar | PSI |

|---|---|---|---|

| Hydrapak PH-1–G | Hyrapak Gauge | 0-1000 | 14,500 |

| Hydrapak PH-2–G | Hyrapak Gauge | 0-700 | 10,000 |

| Hydrapak PH-3–G | Hyrapak Gauge | 0-552 | 8000 |

| Hydrapak PH-4–G | Hyrapak Gauge | 0-448 | 6,500 |

| Hydrapak PH-5–G | Hyrapak Gauge | 0-310 | 4,500 |

| Hydrapak PH-6–G | Hyrapak Gauge | 0-172 | 2,500 |

| HPK10B | Hydrapak Cistern | 5 litre tubular frame | |

| Hydrapak HPK12B | Hydrapak Cistern | 9 litre tubular frame | |

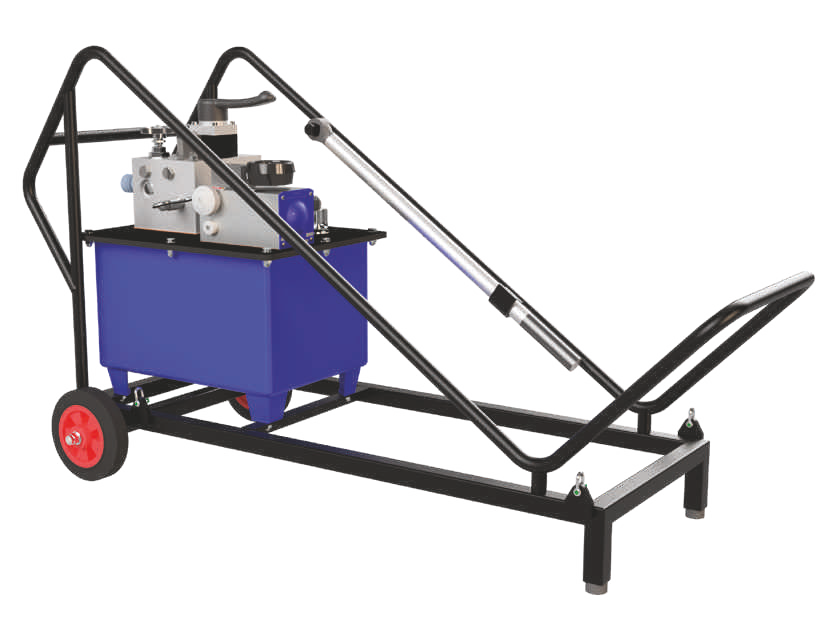

| Hydrapak HPK2 | Hydrapak Skid | ||

| Hydrapak HPK3 | Gauge Fixing Kit | ||

| Hydrapak HPK4 | Hydrapak Cistern | 1 gallon | 5 litre |

| Hydrapak HPK5 | Hydrapak Cistern | 2 gallon | 9 litre |

| Hydrapak HPK6 | Hydrapak Cistern | 4 gallon | 18 litre |

| Hydrapak HPK7 | Hydrapak Cistern | 6 gallon | 27 litre |

| VPR1 | Hydrapak Relief Valve |