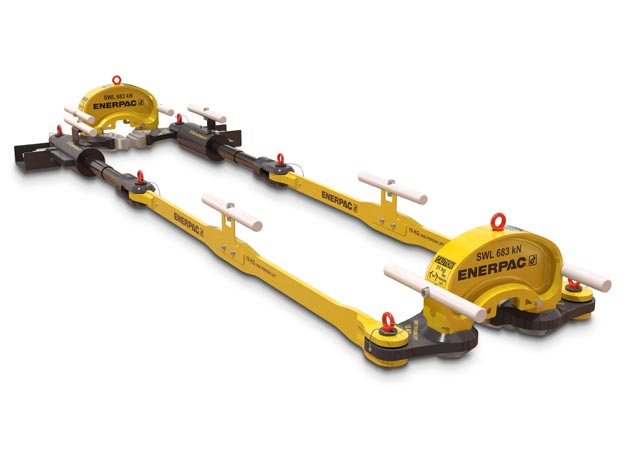

The Enerpac RP70A is a lightweight Rail Stressing Kit that is designed for railway maintenance engineers with stressing, welding, rail failure repairs and servicing needs. Designed to be both durable and easy to assemble, its components are up to 3 times lighter than similar kits. With components 25% lighter than previous models, they are light enough to be lifted, carried, and assembled by a single person.

Lightweight design without sacrifice to performance

The switch to lighter weight double-acting aluminium cylinders eliminates the potential damage from weld splatter caused during operation. The RP70A features a lightweight steel sleeve to shield the cylinders from damage, extending the life of the unit while still benefitting from weight savings gained from aluminium cylinders.

Easy to transport, easy to assemble

An optional steel transport cage has been designed to securely store each stressor kit component for safe and easy transport. Cages can be stacked for space-saving storage when kits are not in use. Rail engineers often need to access rail sections where manual handling to assemble the kit is the only way to install the rail stressor on site.

With the RP70A being a modular kit, extra attention has gone into ensuring it can be easily assembled without the need for additional tools and colored lift handles making the assembly process intuitively easy and inherently streamlined in less than 2 minutes.

A clean solution for increased safety and less impact on environment

A cordless Enerpac ZC pump (with its market-leading lithium-ion battery) pairs perfectly with a fully assembled RP70A to provide a certified rail stressing solution that has a 70-ton pulling force, 35-ton pushing force, below 80dBA max noise level and zero emissions.

https://hi-press.co.uk/wp-content/uploads/2021/03/hydraulic-cylinders-and-jacks.webp

382

681

Hi-Press Hydraulics Enerpac Distributors

https://hi-press.co.uk/wp-content/uploads/2023/02/Hi-Press-Hydraulic-Logo-2023-4-3.svg

Hi-Press Hydraulics Enerpac Distributors2025-06-24 16:14:262025-10-13 11:23:55Types of Enerpac Hydraulic Jacks

https://hi-press.co.uk/wp-content/uploads/2021/03/hydraulic-cylinders-and-jacks.webp

382

681

Hi-Press Hydraulics Enerpac Distributors

https://hi-press.co.uk/wp-content/uploads/2023/02/Hi-Press-Hydraulic-Logo-2023-4-3.svg

Hi-Press Hydraulics Enerpac Distributors2025-06-24 16:14:262025-10-13 11:23:55Types of Enerpac Hydraulic Jacks