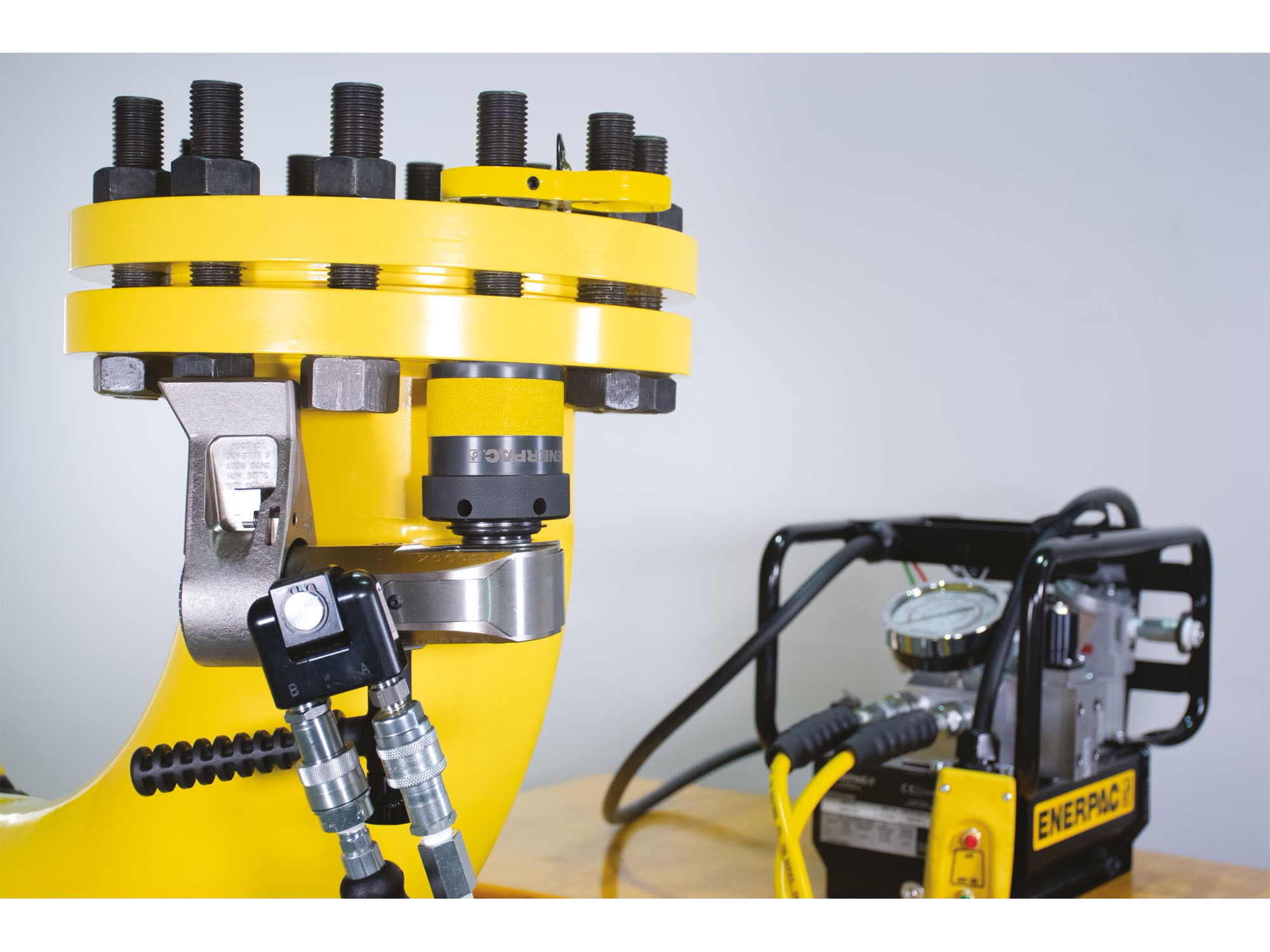

Flange spreading tools – (sometimes referred to as flange splitters or flange separators), are a useful addition to the on-site engineer’s arsenal of flange maintenance tools. These industrial tools are available in a range of configurations, and as the name suggests they’re used to assist in the separation of pipe flange joints. Typical projects include pipeline construction, commissioning, routine maintenance or when valves or pumps need to be replaced.

Types of flange spreader

Three common types include the expanding wedge type, expanding collets, and Mini-gap flange spreaders that use a fixed size wedge. The expanding wedge type are available with either a hydraulic cylinder, or using a mechanically operated mechanism. The expanding collet and mini-gap types use mechanically operated mechanisms only.

How flange spreaders work

The information provided here is just to provide a basic insight into how the products are used. As you might expect, only personnel deemed competent in the use of hydraulic equipment should use these tools. Manufacturer’s operating instructions should be followed very closely.

Using the wedge type of flange spreader

See the following video created by Equalizer International.

Video ©Equalizer. Mirage has no connection with may adverts that may appear during the video.

Before attaching the flange spreader, ensure at least two flange bolts remain in place with nuts loosened sufficiently to enable flange work to be carried out. Leaving these in place will help to reduce unwanted lateral flange movement during flange spreading and prevent existing gaskets from dropping below.

- Determine the most appropriate positioning of the tools around the joint. A minimum of 2 flange spreaders should always be used. These are prevented from dropping by using lanyards provided.

- To determine which flange spreader is needed, measure the flange access gap.

- Place the spreader tool into the access gap, with the full width of the selected step fully inserted up to the heel.

- Spread the flanges apart by actuating the tool.

- Once the joint has been opened to the desired distance Safety Blocks can be inserted into the flange joint.

- Ensure the full width of the selected Safety Block step is fully inserted before gradually retracting the tool until the flange load has been applied to them.

https://hi-press.co.uk/wp-content/uploads/2021/06/SG11TMSTD.jpg

705

940

Hi-Press Hydraulics Enerpac Distributors

https://hi-press.co.uk/wp-content/uploads/2023/02/Hi-Press-Hydraulic-Logo-2023-4-3.svg

Hi-Press Hydraulics Enerpac Distributors2023-11-20 14:27:122023-11-20 15:57:14Equalizer Flange Spreading Tools by Enerpac

https://hi-press.co.uk/wp-content/uploads/2021/06/SG11TMSTD.jpg

705

940

Hi-Press Hydraulics Enerpac Distributors

https://hi-press.co.uk/wp-content/uploads/2023/02/Hi-Press-Hydraulic-Logo-2023-4-3.svg

Hi-Press Hydraulics Enerpac Distributors2023-11-20 14:27:122023-11-20 15:57:14Equalizer Flange Spreading Tools by Enerpac